My 1537G Hotbalst US Stove Burning Nut Coal

- gitrdonecoal

- Member

- Posts: 506

- Joined: Fri. Oct. 16, 2009 4:35 pm

- Location: Elba, NY

- Hot Air Coal Stoker Stove: Keystoker 90

something I have to do with my 1557 is poke from underneath the bed using a homemade poker. it is just a 4 foot long piece of 1/4" rebar material with a 4" bend at the end. I then poke and even slice between the shaker grates and the shaker grate framework. works really good, food for thought

-

LiftedAWDAstro

- Member

- Posts: 171

- Joined: Mon. Feb. 09, 2009 5:02 pm

- Location: New Haven, NY

- Hot Air Coal Stoker Furnace: Keystoker Koker 160

- Coal Size/Type: Rice

I will be making a new poker. The one I currently use is too wide to poke up through. Thanks, mudman.

Theo, I found it at work. It was an old one removed from a piece of equipment. That is the reason it reads all the way up to 2" WC. A range of 0 to .2" WC is plenty. I do not know the cost on one of these but I suspect it is in the $75 range.

Theo, I found it at work. It was an old one removed from a piece of equipment. That is the reason it reads all the way up to 2" WC. A range of 0 to .2" WC is plenty. I do not know the cost on one of these but I suspect it is in the $75 range.

One thing you might consider is to use a poker through the loading door and push through the ashes to just above the grates. Rake back and forth a bit over the top of the grates every day or 2. Youll be amazed how the level drops. Shake it down good and reload. Mine works ALOT better since I started doing this. Make sure your burning good before doing this like before your going to reload but your fire is still going good.

Lifted,

On your 1537G, does the front and rear firebox liner sit on top of the firebrick, or does

the firebrick butt up against the liner(s) (the cast end pieces in the firebox)?

Just picked up a brand new 1537G, going to get it in the basement and assemble

it tomorrow.. Will primarily be a wood burner, but will burn coal from time to time..

Putt...

On your 1537G, does the front and rear firebox liner sit on top of the firebrick, or does

the firebrick butt up against the liner(s) (the cast end pieces in the firebox)?

Just picked up a brand new 1537G, going to get it in the basement and assemble

it tomorrow.. Will primarily be a wood burner, but will burn coal from time to time..

Putt...

-

LiftedAWDAstro

- Member

- Posts: 171

- Joined: Mon. Feb. 09, 2009 5:02 pm

- Location: New Haven, NY

- Hot Air Coal Stoker Furnace: Keystoker Koker 160

- Coal Size/Type: Rice

The firebrick lays against the sides and just butts up to the cast pieces at the ends.

I am still waiting on the new grates and combustion blower to show up. I hope they are here before the weekend as I will be on my week off! I wanna burn coal in this before it gets too hot!

I am still waiting on the new grates and combustion blower to show up. I hope they are here before the weekend as I will be on my week off! I wanna burn coal in this before it gets too hot!

-

LiftedAWDAstro

- Member

- Posts: 171

- Joined: Mon. Feb. 09, 2009 5:02 pm

- Location: New Haven, NY

- Hot Air Coal Stoker Furnace: Keystoker Koker 160

- Coal Size/Type: Rice

I was doing that but maybe I didn't stir enough to get the ashes down.wnyjim wrote:One thing you might consider is to use a poker through the loading door and push through the ashes to just above the grates. Rake back and forth a bit over the top of the grates every day or 2. Youll be amazed how the level drops. Shake it down good and reload. Mine works ALOT better since I started doing this. Make sure your burning good before doing this like before your going to reload but your fire is still going good.

Thanks Lifted..LiftedAWDAstro wrote:The firebrick lays against the sides and just butts up to the cast pieces at the ends.

I am still waiting on the new grates and combustion blower to show up. I hope they are here before the weekend as I will be on my week off! I wanna burn coal in this before it gets too hot!

Wrestled it in the door, and down the steps, around the corner, and into position.. Going to have to pick up a double male smoke pipe connector

to get it plumbed to the flue... Will probably pick up a baro damper while I am at it... I have a brick chimney, tile lined, about 35 ft high or so, and

it always has a natural draft, even in the summer. Draft is not a problem here..

Putt...

-

LiftedAWDAstro

- Member

- Posts: 171

- Joined: Mon. Feb. 09, 2009 5:02 pm

- Location: New Haven, NY

- Hot Air Coal Stoker Furnace: Keystoker Koker 160

- Coal Size/Type: Rice

Got my parts today!  The grates are seasoning as we speak and will be modified tomorrow and the draft blower kit will be installed as well! There will be more pics tomorrow!

The grates are seasoning as we speak and will be modified tomorrow and the draft blower kit will be installed as well! There will be more pics tomorrow!

Got mine set up, flue plumbed, and lit a "small" fire last night...

Mine was missing the thermodisc, so that is on order along with a baro. damper.

I just plugged in one of the blowers and considering the small fire,

it put out a pretty fair amount of heat. Am seasoning the grates,

so it will be a while before I load it up "for real" ..

..

I do have a number of bags of nut Anth. out in the garage,

so I will see what kind of appetite mine has for coal..

It did heat the basement up rather nicely last night..

Putt...

Mine was missing the thermodisc, so that is on order along with a baro. damper.

I just plugged in one of the blowers and considering the small fire,

it put out a pretty fair amount of heat. Am seasoning the grates,

so it will be a while before I load it up "for real"

I do have a number of bags of nut Anth. out in the garage,

so I will see what kind of appetite mine has for coal..

It did heat the basement up rather nicely last night..

Putt...

-

LiftedAWDAstro

- Member

- Posts: 171

- Joined: Mon. Feb. 09, 2009 5:02 pm

- Location: New Haven, NY

- Hot Air Coal Stoker Furnace: Keystoker Koker 160

- Coal Size/Type: Rice

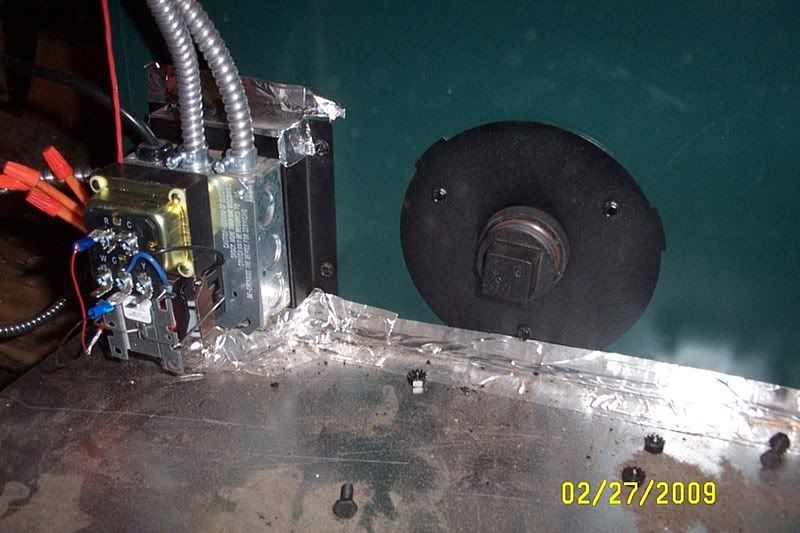

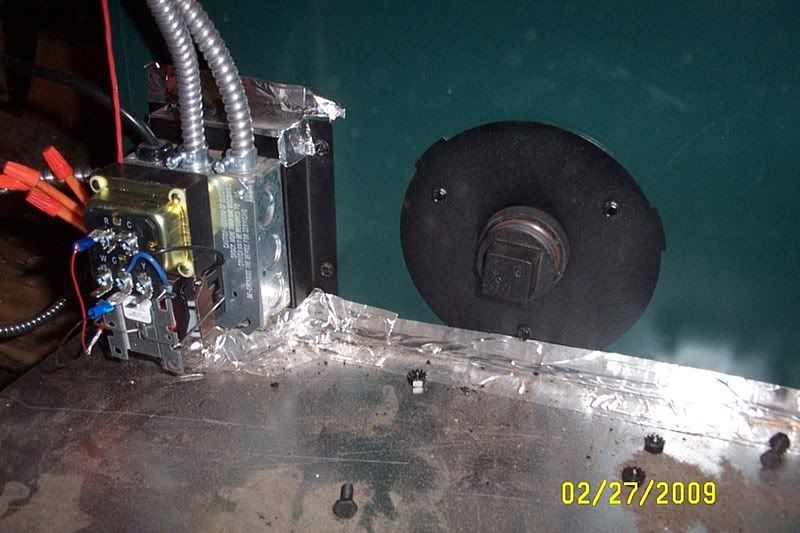

Here are some pics...I am burning wood for now with the draft inducer fan ported in the rear stock location.

Modifying the grates after seasoning in the oven.

Old thermodisc being removed.

Wired in the fan limit control and fan control relay and fan.

Wired up the USSC thermostat.

Modifying the grates after seasoning in the oven.

Old thermodisc being removed.

Wired in the fan limit control and fan control relay and fan.

Wired up the USSC thermostat.

-

LiftedAWDAstro

- Member

- Posts: 171

- Joined: Mon. Feb. 09, 2009 5:02 pm

- Location: New Haven, NY

- Hot Air Coal Stoker Furnace: Keystoker Koker 160

- Coal Size/Type: Rice

I also modified the ash door to accept the DIF...

Took the spinner off

Used the pipe flange adapter supplied to mark 2 holes. I drilled and tapped them for 1/4 - 20 bolts.

Here is the DIF mounted to the door. The pipe flange adapter is not used on the ash door. When I wired the DIF, I used a longer piece of MC cable than was supplied so I can simply unbolt the DIF from the rear, plug the hole and move the DIF to the ash door after removing the spinner.

Here is the pipe plug location in the rear.

Took the spinner off

Used the pipe flange adapter supplied to mark 2 holes. I drilled and tapped them for 1/4 - 20 bolts.

Here is the DIF mounted to the door. The pipe flange adapter is not used on the ash door. When I wired the DIF, I used a longer piece of MC cable than was supplied so I can simply unbolt the DIF from the rear, plug the hole and move the DIF to the ash door after removing the spinner.

Here is the pipe plug location in the rear.

i have this exact same furnace... You have me thinking now!!! So all you did was drill and tap the grates for a small set of bolts? What about the ash door? Can you still open it completely? I take it this is just drilled and tapped too? How about electrical wiring, is the play in the wire enough to facilitate de-ashing?