Woot!

Now for the hard part

I've set the feed rate to get '1/2 inch' of ash at the end of the grate.

I pulled the burner wire, and set the rheostats both on min. (I had to turn on the delay, that hadn't been set. Now I feel like Spartacus for figuring out how to do that

I've set the 'off' switch to 7 minutes, and the 'on' switch to ~30 seconds.

Anyone else running that far off the factory specs?

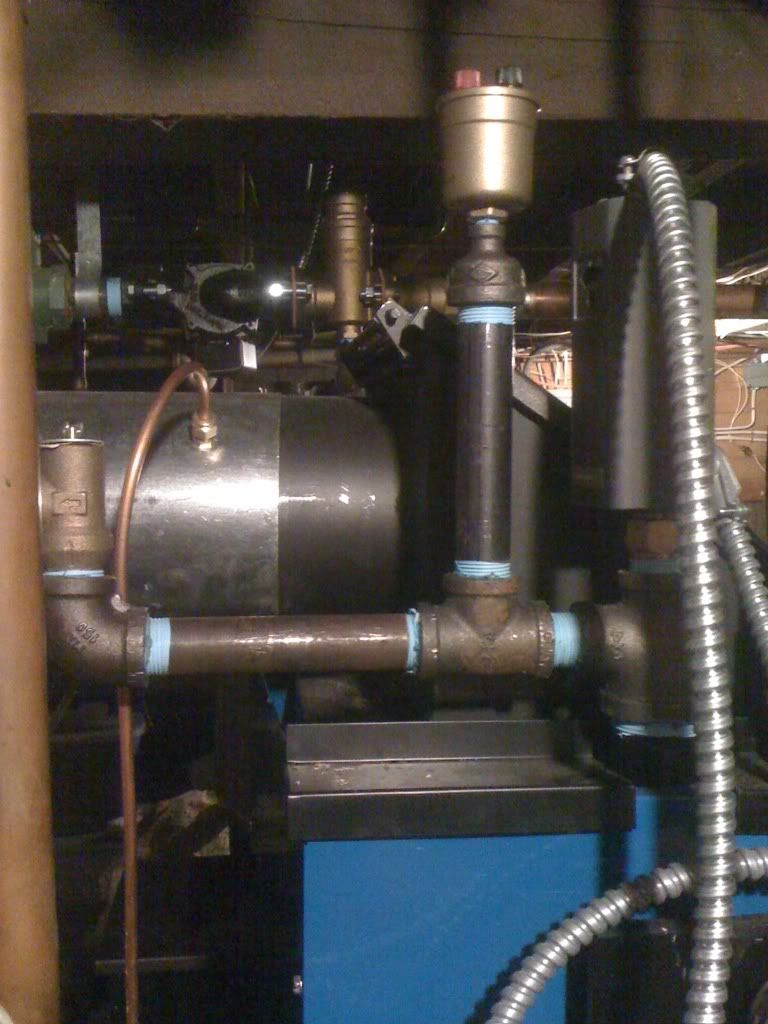

Second (minor) problem is that the high limit aquastat (6006A) isn't responding anywhere near the temp that's reading on the 7224. I have it set for 150f, it's kicking in at 173f, and doesn't shut off until the temp in the boiler is ~100-105f.

Which means as soon as it shuts off, the burner comes back on again.

I think it has something to do with the way Axeman want's the older expansion tanks piped in, because the well that the 6006A sits in takes forever to cool down. I mean like 3 minutes after the boiler temp reads 100f on the gauge, the high limit finally turns off.

Any advice would be appreciated.