thanks to rustyrelics for unearthing these here on NEPA, now I don't have to keep struggling to scan them.

Riteway Stove Manual.pdf

Riteway Brochure and User Manual

-

KingCoal

- Member

- Posts: 4837

- Joined: Wed. Apr. 03, 2013 1:24 pm

- Location: Elkhart county, IN.

- Hand Fed Coal Stove: 1 comforter stove works all iron coal box stove, seventies.

- Baseburners & Antiques: 2014 DTS C17 Base Burner, GW #6, GW 113 formerly Sir Williams, maybe others at Pauliewog’s I’ve forgotten about

- Coal Size/Type: Nut Anth.

- Other Heating: none

- rustyrelics

- Member

- Posts: 64

- Joined: Sat. Dec. 28, 2013 2:27 pm

- Baseburners & Antiques: Scranton Stove Works base heater

- Other Heating: Franklin wood stove

thanks for link thread post. another thing I found in the owners manual for the Riteway. read the part about burning wood. it says fill the bottom 2" of firebox over the grates, with soil or ashes, to protect the grates. then is says after raking keep 2" of ash on top of grates to protect them at all times, with wood fire. ok that means the under fire through grate air is for all effective purposes blocked, if directions are followed. and when that stove is burning wood, its relying 100% on the draft louvers to feed the top of a wood fire draft, then burning the smoke again in the combustion flue using fresh air from the secondary fixed drilled draft ports in the flue. this logic ties in with what Harman told me about their SF250 stove yesterday. using the fire door vents only to burn wood. I'm going to have to start a wood fire just to see how this thing burns. now the biggie. it says when reloading wood fire, on warm days when a full batch may burn for days....etc. for DAYS ? wow. that thing must get some serious wood burning mileage. then it does on to say keep a wood fire 2" below the combustion flue outlet. the stove sounds like it was designed to keep a very low smoldering fire in it and reburn the smoke and get maximum time from a load of wood. they say on warm days reload the stove every 12 hours. I've yet to see a wood stove that would last 12 hours on one load of wood. this I'm going to test out. it's an interesting piece of hardware that's for sure.

-

KingCoal

- Member

- Posts: 4837

- Joined: Wed. Apr. 03, 2013 1:24 pm

- Location: Elkhart county, IN.

- Hand Fed Coal Stove: 1 comforter stove works all iron coal box stove, seventies.

- Baseburners & Antiques: 2014 DTS C17 Base Burner, GW #6, GW 113 formerly Sir Williams, maybe others at Pauliewog’s I’ve forgotten about

- Coal Size/Type: Nut Anth.

- Other Heating: none

toward the keeping of a wood fire 2" below the flue exit, that is an ill conceived descriptive on their part, what they mean is, keep the ash and ember level 2" below the flue exit.

the brochure I have shows an end view of the stove loaded all the way to the top of the door with wood.

i have never heard of any one getting more than 12 hrs. of burn time out of wood in one of these in any weather that actually required steady heat at a rate of 50 to 70* above ambient. all reports confirm the need to keep small fires regularly refilled to keep from burning the structure down from the excess creosote at constant low fire rates.

when burning wood these really do need to be kept in the 400* range with just enough good dry wood in it to go as little time as you can stand.

the brochure I have shows an end view of the stove loaded all the way to the top of the door with wood.

i have never heard of any one getting more than 12 hrs. of burn time out of wood in one of these in any weather that actually required steady heat at a rate of 50 to 70* above ambient. all reports confirm the need to keep small fires regularly refilled to keep from burning the structure down from the excess creosote at constant low fire rates.

when burning wood these really do need to be kept in the 400* range with just enough good dry wood in it to go as little time as you can stand.

- rustyrelics

- Member

- Posts: 64

- Joined: Sat. Dec. 28, 2013 2:27 pm

- Baseburners & Antiques: Scranton Stove Works base heater

- Other Heating: Franklin wood stove

agreed and that goes for any wood burner. minimum flue temp should be 275 to prevent creosote. a flue temp of 275 is a stove temp of ? at least 550 for a 50% efficient stove. you were being generous at 450, that would mean its a very good stove that has about 60% efficiency  thats the problem with wood, simmer it down and is plugs up the flue in no time. the new EPA wood stoves can hit that no problem due to their pollution mandates. they are doing 70% plus or minus 10% otherwise they aren't legal to sell for wood. that tells us all something about the coal stoves that are now being sold as "coal only". they aren't even 60% efficient with wood, otherwise they'd be EPA legal for wood and be dual fuel. coal on the other hand is more efficient because the fuel inherently burns cleaner. any run of the mill new coal stove can hit 60-70% efficiency if it has a heat exchanger, internal baffle, and fan. and they can do it without an MPD or baro.

thats the problem with wood, simmer it down and is plugs up the flue in no time. the new EPA wood stoves can hit that no problem due to their pollution mandates. they are doing 70% plus or minus 10% otherwise they aren't legal to sell for wood. that tells us all something about the coal stoves that are now being sold as "coal only". they aren't even 60% efficient with wood, otherwise they'd be EPA legal for wood and be dual fuel. coal on the other hand is more efficient because the fuel inherently burns cleaner. any run of the mill new coal stove can hit 60-70% efficiency if it has a heat exchanger, internal baffle, and fan. and they can do it without an MPD or baro.

- rustyrelics

- Member

- Posts: 64

- Joined: Sat. Dec. 28, 2013 2:27 pm

- Baseburners & Antiques: Scranton Stove Works base heater

- Other Heating: Franklin wood stove

KC, worst case scenario for any Riteway or Hitzer clone- it can be modified into a basic coal or wood burner using the top outlet,. maybe an added external mpd too. then it would be very similar to the old Sears and Atlanta brand box stove circulators. I had one and it heated well for what it was, and didnt even have an mpd, ran it straight pipe. the draft control was very precise with the tstat control, really didnt need an mpd. when I decided to sell it, it sold the same day to some old guy for his house. for all I know he's still using it. here's what a Riteway can easily be converted into. this is a schematic for the old Sears and Atlanta box stove models. they had a thermostat bimetal controlled inlet draft control just like a Riteway, but were direct draft side outlet, no recirculating flue chamber. that sucker would boil you out of the house if you cranked 'er up. IIRC the firebricks went right up to the top outlet pipe. I clearly remember shoveling coal in, and a few unburned pieces of coal sitting inside the outlet pipe hole. I would have to reach in with welder glove and knock them back into the fire.  it had no above fire secondary air so had to be careful opening the door after refills. I would crack it open, wait, then open it. that would gently ignite the methane little blue flames.

it had no above fire secondary air so had to be careful opening the door after refills. I would crack it open, wait, then open it. that would gently ignite the methane little blue flames.

-

kmholet

- New Member

- Posts: 2

- Joined: Sat. Mar. 07, 2015 10:52 am

- Other Heating: Riteway 37 Wood Stove

Does the manual discuss the theory of operation? I've owned a Riteway 37 for about 15 years. Just this year 2 1-inch firebrick (one of the broken in half) showed up in the firebox near the air inlet port. I'm trying to figure out where they came from. Perhaps to separate the inlet from the secondary combustion flue? This year the stove has been burning horribly, with a very poor draft. Any thoughts? thanks.

-

KingCoal

- Member

- Posts: 4837

- Joined: Wed. Apr. 03, 2013 1:24 pm

- Location: Elkhart county, IN.

- Hand Fed Coal Stove: 1 comforter stove works all iron coal box stove, seventies.

- Baseburners & Antiques: 2014 DTS C17 Base Burner, GW #6, GW 113 formerly Sir Williams, maybe others at Pauliewog’s I’ve forgotten about

- Coal Size/Type: Nut Anth.

- Other Heating: none

can you open the attachment in the first post of this thread ?

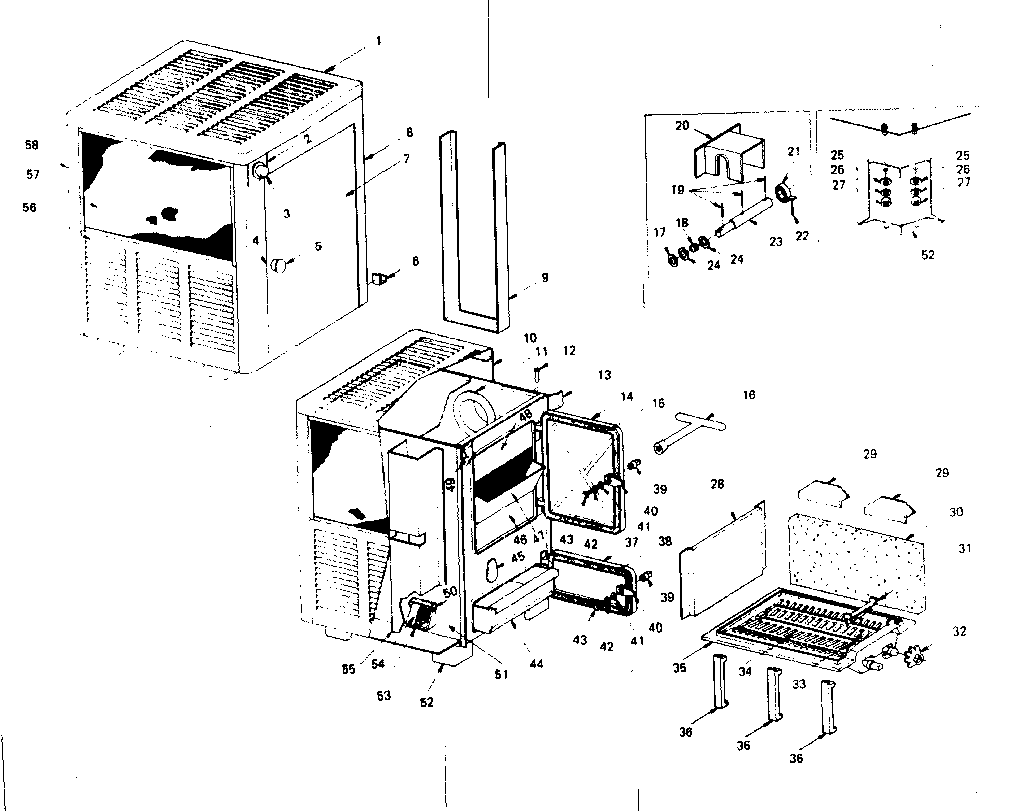

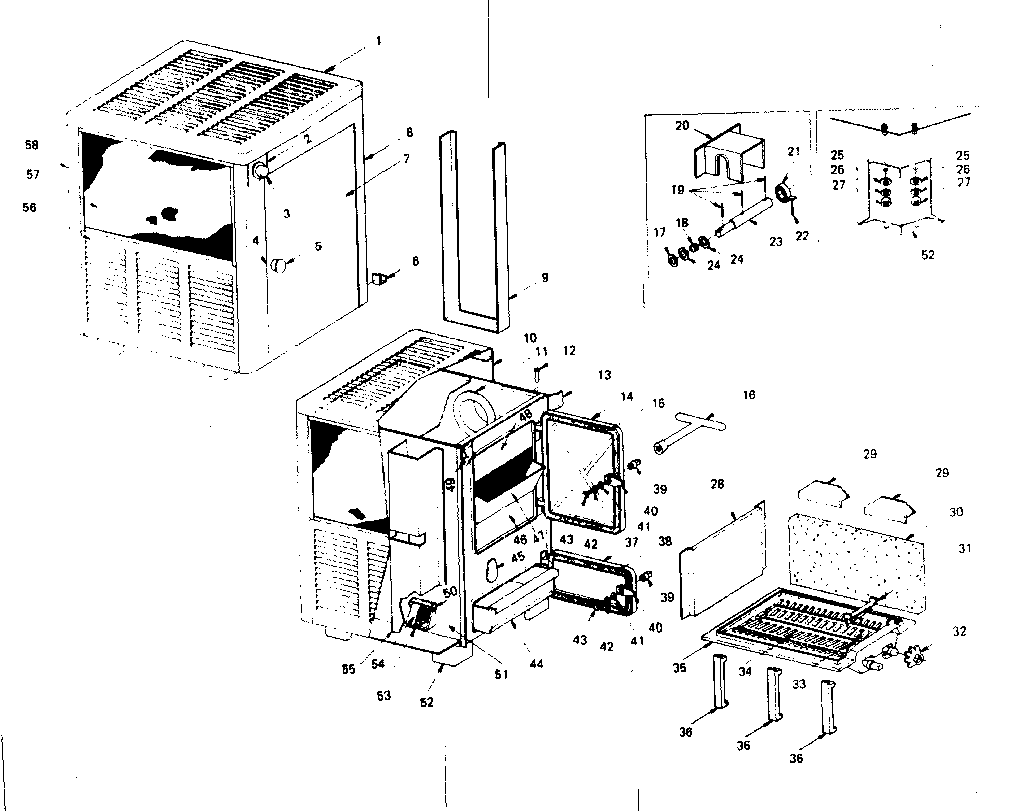

if you can, scan down to page 13, in the middle of the exploded view of all the parts for a #37 is the ring of fire bricks. can you tell us from that which ones are missing or broken, or can you get a well lit pic of your actual stove ?

if it is the 2 bricks that are slanted, you will be needing to replace them for sure and i'm amazed you can operate the stove at all with them broken or misplaced.

steve

if you can, scan down to page 13, in the middle of the exploded view of all the parts for a #37 is the ring of fire bricks. can you tell us from that which ones are missing or broken, or can you get a well lit pic of your actual stove ?

if it is the 2 bricks that are slanted, you will be needing to replace them for sure and i'm amazed you can operate the stove at all with them broken or misplaced.

steve

-

kmholet

- New Member

- Posts: 2

- Joined: Sat. Mar. 07, 2015 10:52 am

- Other Heating: Riteway 37 Wood Stove

Thanks, KingCoal! I had in the meantime downloaded the brochure that you mentioned and also saw the two slanted bricks and realized that those bricks must be the only barrier separating the inlet from the flue! One of those two bricks was broken in half. The other was fine. I just bought some replacement firebrick and plan to burn a load tonight to try it out. The other clue was that the only way I could get a decent burn was to crack open the bottom door, and it burned better with the inlet thermostat turned DOWN (closing the air inlet "bypass"). So indeed I think that was the problem. I typically have a good fire with a 20 ft. masonry flue. I normally go up on the roof in the fall and find that the little creosote that I had had already fallen to the bottom over the summer. I've never had any significant build-up.

I've been reading some of the other posts on this site that discuss the burn duration and how to get the wood to burn cleanly. I too find that if I load the stove up at night and turn the inlet down just a bit it can indeed burn all night and then some. HOWEVER, I prefer to control the heat production by reducing the amount of fuel. The smaller the fire, the less the heat. If you have a lot of fuel, then you need to reduce the oxygen, which leads to poor combustion and the build up of creosote. If you reduce the fuel, what is there is left to burn hot and cleanly (so long as the stove and flue are hot enough). All in all, I'm tickled with the Riteway 37. It sits about 4 feet from the air handler of my heat pump, and I have a thermostatically controlled air inlet there. 100 degree air is drawn into the air handler, through the filter and then distributed through the house. The stove handles a large capacity when necessary, has excellent heat transfer, and easy ash removal with the fire still going if necessary. I did also note that the top gasket is leaking a little bit. I'll need to replace it this summer.

Thanks for your reply!

Ken Holet

Earlysville, VA

I've been reading some of the other posts on this site that discuss the burn duration and how to get the wood to burn cleanly. I too find that if I load the stove up at night and turn the inlet down just a bit it can indeed burn all night and then some. HOWEVER, I prefer to control the heat production by reducing the amount of fuel. The smaller the fire, the less the heat. If you have a lot of fuel, then you need to reduce the oxygen, which leads to poor combustion and the build up of creosote. If you reduce the fuel, what is there is left to burn hot and cleanly (so long as the stove and flue are hot enough). All in all, I'm tickled with the Riteway 37. It sits about 4 feet from the air handler of my heat pump, and I have a thermostatically controlled air inlet there. 100 degree air is drawn into the air handler, through the filter and then distributed through the house. The stove handles a large capacity when necessary, has excellent heat transfer, and easy ash removal with the fire still going if necessary. I did also note that the top gasket is leaking a little bit. I'll need to replace it this summer.

Thanks for your reply!

Ken Holet

Earlysville, VA